Project

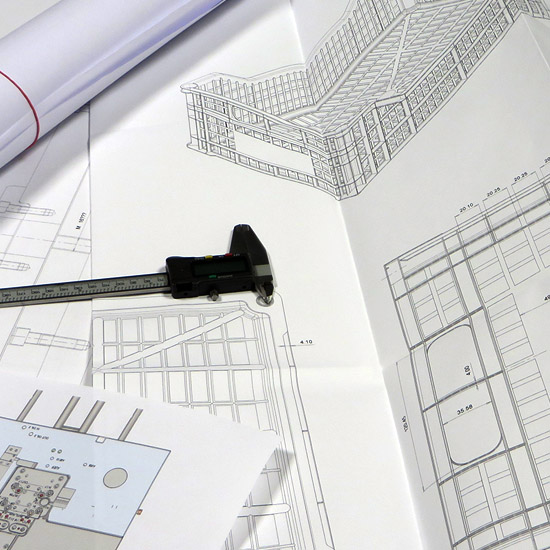

TGS Stampi s.r.l. has his own in-house technical office to develop the article design and the mould project.

The article design is made in cooperation with the customer and accordingly with his specific demand and all the necessary personalization.

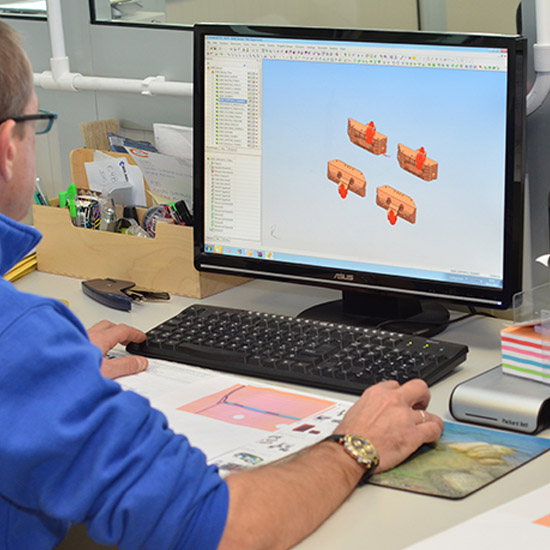

The mould project is made thanks to innovative systems such as CAD-CAM, CIMATRON-E, CIMATRON-IT.

The software allow the company to realize all the models and programs necessary to set up the CNC machines to manufacture the moulds.

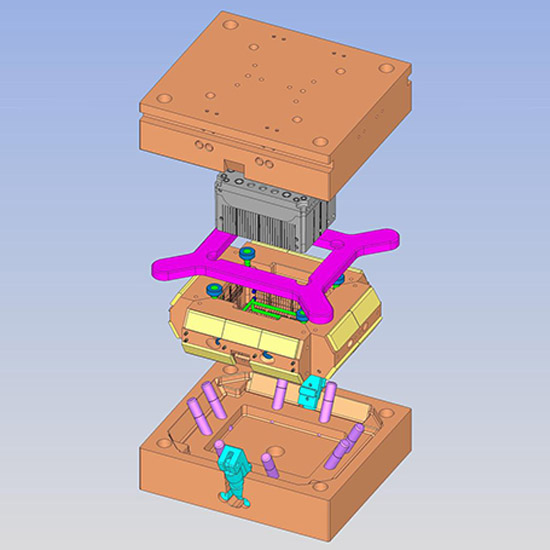

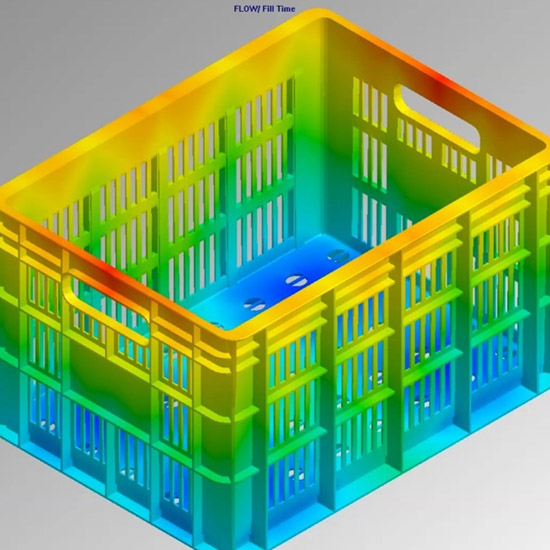

Before to proceed with the mould project, the technical office makes two analyses: structural analysis of the article and mould flow analysis through the software Moldex.

Production

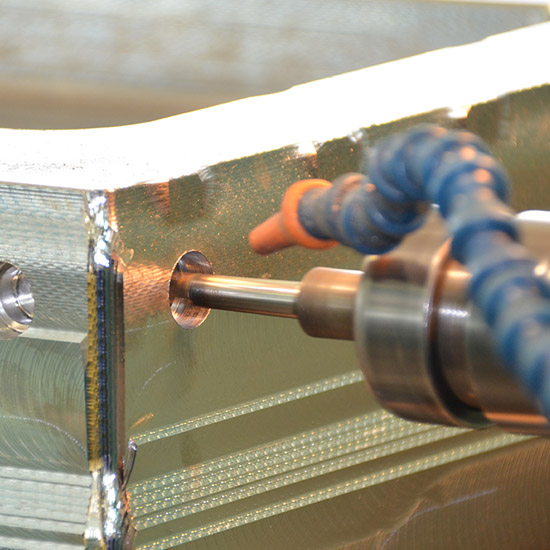

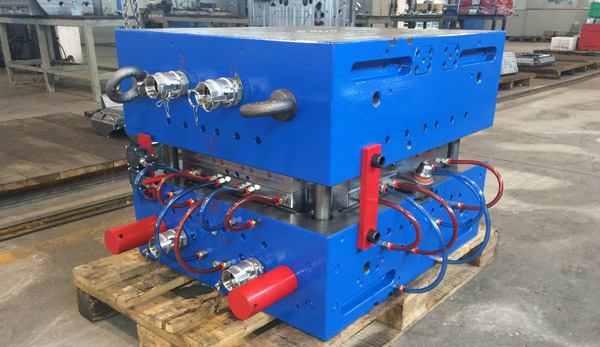

TGS Stampi Srl provides maintenance and manufacturing from “zero” of all kind of moulds. To allow a fast and perfect production, the company is equipped with advanced and technologies machines and tools:

- - Paventa Speed 2000 Plus milling machine

- - Sachman T10 cnc milling machine

- - Sachman T10 HS cnc milling machine

- - Sachman T314HS cnc milling machine

- - FPT Tessen 6 axes with rotating table cnc milling machine

- - SKV712HE Cnc milling workstation

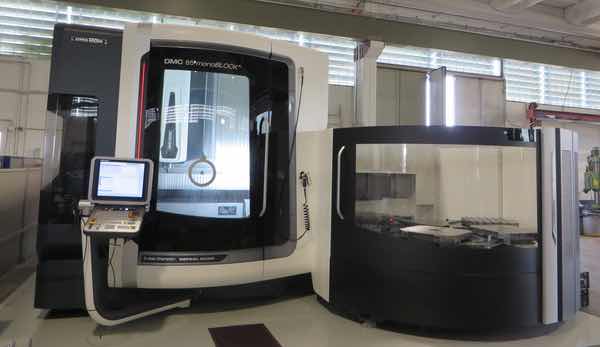

- - Milling DMC 85 MONOBLOCK, 5 axes continues, 6 pallet automatic changer system, swiveling and rotary table

- - I.M.S.A "MF 1000 A" deep hole drilling machine

- - Tangential grinding machine

- - Bergonzi TM50 pillar drilling machine

- - Radial drilling machine

- - “CMT-USRUS TC 600” Cnc lathe machine

- - Saw

- - Manual Sharpener

All workers and the owners are specialized in every kind of working phases and with different materials.

The TGS Stampi’s team offer a complete service with mould maintenance and advice on site or at customer’s site.

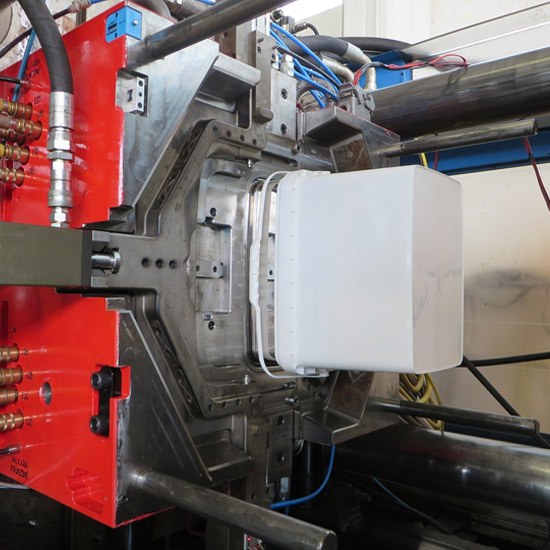

To have a complete check of the final article, before the mould shipment, even for new and repaired moulds, TGS Stampi s.r.l. makes the mould test to guarantee the excellent performance.

Mould Maintenance

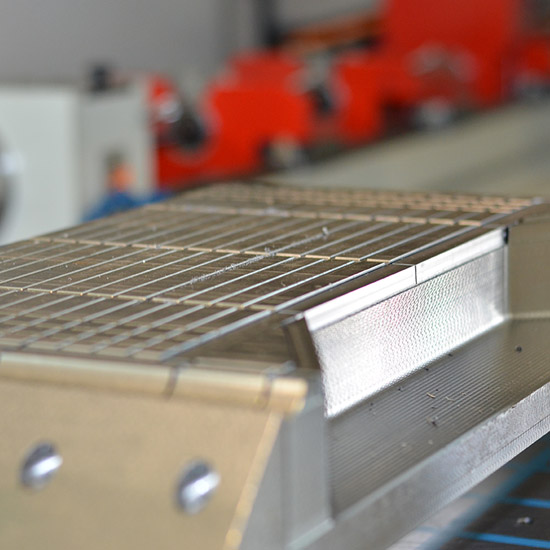

TGS Stampi s.r.l. is specialized and equipped for maintenance and repairing works on high-productivity moulds with fast cycle time.

The company refurbish old concept moulds for such products as one-way crates and packaging containers, optimizing the article design, the weight and the quality of the article. The production cycle time is speeded up with innovative methods and materials.

New solutions to ease moulding by adapting the mould to increasingly fast injection machines.

Specialized working team is every time available to support the customers in their small daily problems.